Every day, you should check your bearings. Note any anomalies such as noise, temperature of bearings or even vibration.

Check for any debris that may be in the suction tube (such as twigs or stones). Popping or high pitched clicking sounds can be a sign of cavitation.

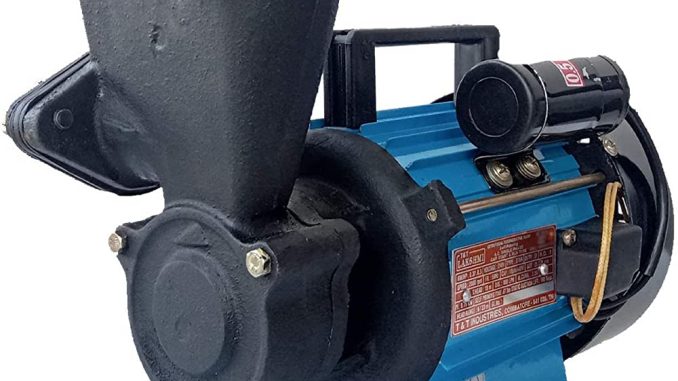

Essential Pump Care

Contact a professional immediately if your water pumps are suffering from issues that suggest they’re nearing their end-of-life, such bom cuu hoa as lower water pressure. A simple problem may be caused by an electrical circuit breaker that is tripping, or the pressure tank being empty. Getting the issue addressed promptly can avoid the requirement for costly repairs.

Regular checks of the pump’s water supply are essential to identify potential damages or other anomalies. To clean and remove any buildup of sand, or any other particles on the pump, it is recommended to conduct inspections. It is also recommended that the water pump be inspected for rust cracks, cracks or other signs of damage.

The wear and tear of the bearings could cause strange noises or vibrations within your water pump. Cavitation could cause your pump to fail in efficiency and power, while also shortening its lifespan. Ignoring the signs could lead to more serious issues.

Maintenance Prevention

Pumps are essential in keeping facilities running however if not maintained properly and maintained, they can fail quickly and become very expensive. Conducting preventative maintenance will help reduce emergency expenses including staff and repair crews and overtime payments machines shut down as well as overnight delivery of parts and many more.

Regular inspections are essential to ensure the performance over time of your pumps. They will be able to spot a vast variety of issues from loud noises and gravel grinding in your pump (cavitation damage) to the sound of bearings sealing chamber leaks the sound of vibrations, or even a reduction in the flow of water.

One of the best ways to make sure that your pumps run at optimum efficiency is by implementing a comprehensive routine of daily, weekly and monthly pump maintenance. Included in this are visual inspections as well as the lubrication process and differential pressure tests and evaluations. In addition, it is important to check the alignment of the shaft and motor bearings. You should also check the shaft bearings for cracks, grooves or pits and ensure that the seal’s mechanical integrity isn’t damaged.

Tips for making sure that pumps last longer

Prevention is the most effective option to reduce the risk of problems related to water pumps. The tasks include contamination of the coolant by oils or other substances as well as checking the water tank for air pockets, and examining the impeller blades regularly. These tasks should be performed regularly to keep water flowing and prevent costly repair bills.

Another important aspect of preventive maintenance is storing the pump properly. It is crucial to empty the casing so that it can prevent rust or other corrosion from harming the internal components. Pumps can be kept in a drier environment to help reduce the chances of corrosion.

It is also a good practice to inspect the water pump on a regular on a regular basis. Clean oil is lubricant for moving parts, and can help reduce friction that can lead to wear and wear.

Maintenance of Industrial Water Pumps

Pumps play a vital role in the running of your company. It’s not difficult to forget their importance. Failure of a pump can lead to serious problems for your business.

A thorough checklist of your maintenance is vital to ensure that your equipment running in top condition. This can help avoid costly repairs, lost production as well as unnecessary expenses.

Inspecting a pump for leaks and proper lubrication, wear to the drive system and vibrations, noise and electrical connections is important. If your pump’s performance is not optimal, you’ll be able to determine this by monitoring operating parameters, such as differential pressure, rpms, efficient points and power requirements and the voltage.

Alongside draining and replacing mechanical seals maintenance program should include draining wet ends. The mechanical seal is well-lubricated, and will prevent excessive corrosion. Consider storing the equipment on pallets or blocks in order to reduce the vibrations created by the flooring and other equipment. Equipment can be stored directly on the floor but you should cover it up by the use of a cover.